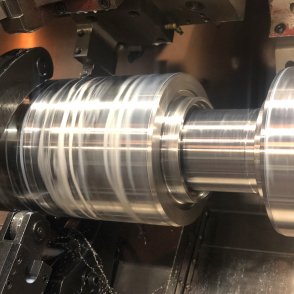

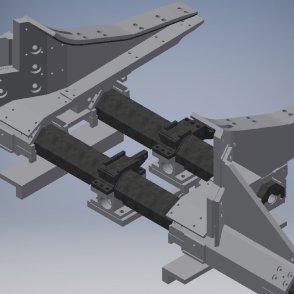

At Kocsis Machine, we do things big. Since 1967 we have employed the best and brightest minds in the industry to handle precision-machining and assembly services for medium to large-sized parts across various sectors. The Kocsis technical team consists of market-leading machinists and millwrights, an integrated engineering team, and responsive manufacturing consultants committed to your business success. We offer turnkey solutions by enhancing our core competencies with material sourcing and stocking programs. Our expansive facilities span over 200,000 square feet to deliver top-quality precision machining craftsmanship. Customers who work with Kocsis Machine get access to all equipment on our facilities list, along with our 50-ton lifting capacity, press capabilities of 400 and 800 tons, automated part cleaning, and much more. At Kocsis Machine, there’s only one thing that’s bigger to us than the parts we make — your partnership.